What

After finding my DSi XL in storage I wanted to boot it up and replay some of the games I used to play. Unfortunately the battery was dead and the device was not charging when the AC adapter was plugged in. This led me to test my electrical skills and determine if a bad battery or faulty circuitry was causing the issues.

How

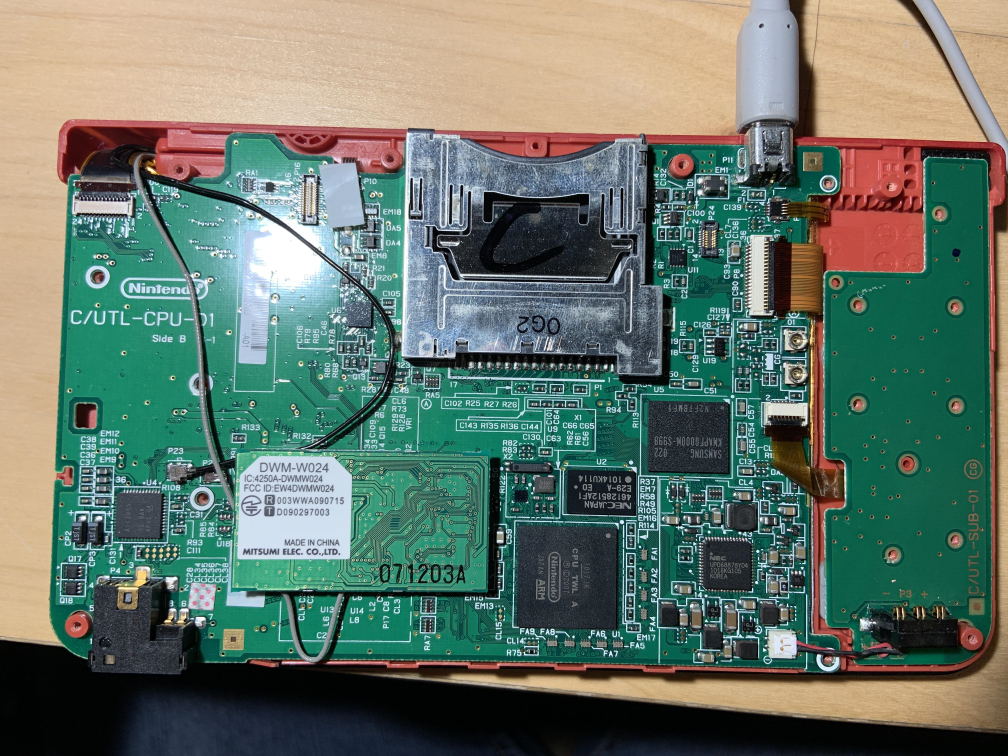

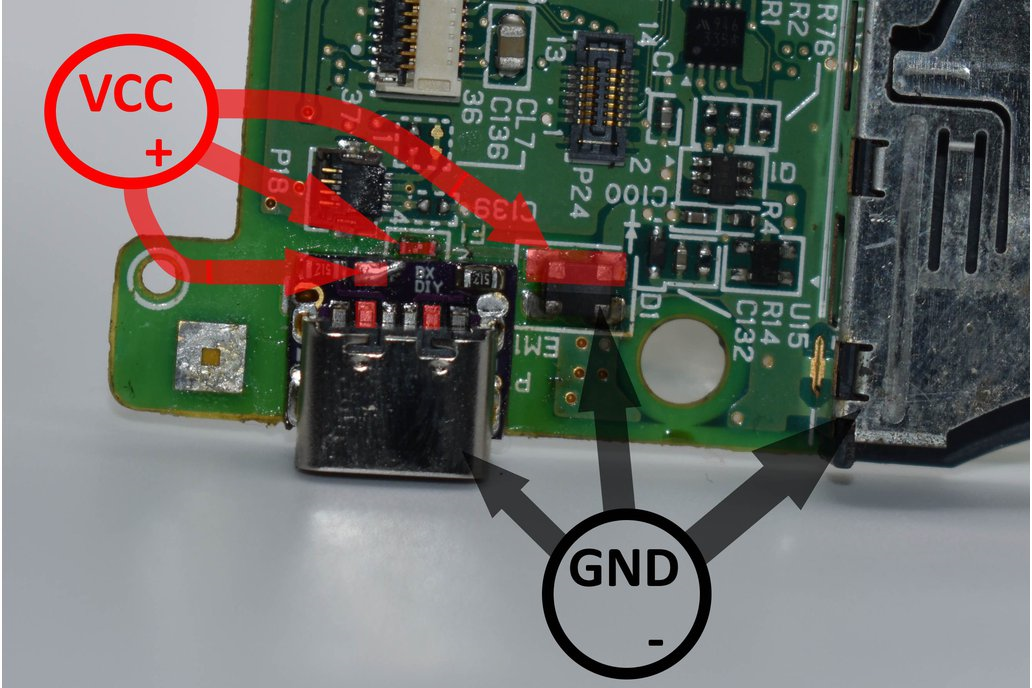

First I removed the screws on the case and visually inspected the components for damage. Everything on the motherboard seemed fine, just a little dusty. The lithium-ion battery appeared to be getting slightly poofy, however, which I recognized as signs of a “spicy pillow”. After properly disposing of the battery in accordance with local regulation I purchased a new battery and tested the circuit in the meantime. With no battery plugged in, I should expect a blinking orange light and 3.7V open circuit voltage on the battery terminals, however, I found no voltage. Tracing back the vias for the charging circuit I passed through two fuses which I verified to be functioning with a continuity test and a square module which I looked up to be a voltage regulator for the charging circuit (5V to 3.7V). After probing the block for a while I got continuity across the block, however, it took a fair bit of poking which I initially accounted for as some dirt on the pad. I also verified that 5V was coming in across the two pins. As everything appeared to be working, I went back to the battery terminals and then read 3.7V but then I shifted the DSi on accident and I read 0 volts again. After some back and forth troubleshooting I determined the voltage regulator had a weak connection on the board (or a cracked solder joint) and when the charger was in the right position I would get continuity. After reflowing the solder joints, I retested and got 3.7V at the output no matter the position of the charging cable.

Reflection

In this project, I learned some valuable skills about tracing circuit boards and using a multimeter to verify expected behavior. In addition, I learned that when I have inconsistent multimeter readings, it will never hurt to reflow the solder joint to ensure a clean, non oxidized solder blob, especially on circuit boards that have been through conditions and 15+ years of use. An improvement I recognize for the future is exactly this, the multimeter rarely lies if you use it right and an inconsistent reading is likely indicative of a poor connection.